The Stainless steel balls are manufactured to very close spherically and tolerance and mirror finished. this result in bubble tight and considerably reduced operating torque.

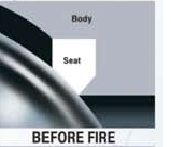

Our Industries fire safe design valve feature secondary metal to metal seat which renders the valve fire safe. An integral metal lip in the configuration of the soft seat is designed to prevent the softening downstream seat from being forced into the port in the event of a fire, when the seats is totally sublimated in a fire the ball moves and rests against the lips, forming a metal to metal seat thus ensuring leak tightness. End connectors or inserts have spirited ends to ensure the concentricity and correct alignment of the ball.

Antistatic Feature

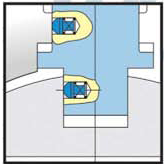

Antistatic FeatureBuild up of static electricity can occur as a result of constant rubbing of the ball against the PTFE seats. This

can be a potential fire hazard, especially while handling inflammable fluids our industries Ball valves built in antistatic design

features.

In general, this is achieved through 30% carbon filled PTFE stem seats and graphite gland packing to provide

electrical continuity between the body and stem /ball, discharge any build up of static charge. In addition, spring loaded

plungers are provided between the stem and the ball in single piece and two piece reduced bore ( 80mm & above ) and full bore ( 50mm & above ) valves.

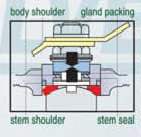

Blow Out Proof Stem

Blow Out Proof StemOur Industries Ball valves have a bottom entry stem design which feature stem insertion from inside th body.

An integral shoulder on the stem seats

against the body, giving it blow out proof integrity.

The line pressure, the lighter the seal. This design offers safety feature superior to top-entry stem design where the line pressure works to break the stem seating.

| VALVE SIZE | RATING | A | B | C | D | T | PCD. | NO. OF HOLES |

| 15m.m. | DIN 10 | 130 | 15 | 45*2 | 95 | 14 | 65 | 4-14.1 |

| 20m.m | DIN 10 | 150 | 19 | 58*2 | 105 | 16 | 75 | 4-14.1 |

| 25m.m | DIN 10 | 160 | 25 | 68*2 | 115 | 16 | 85 | 4-14.1 |

| 40m.m | DIN 10 | 200 | 38 | 88*3 | 150 | 16 | 110 | 4-18.5 |

| 50m.m | DIN 10 | 230 | 49 | 102*2 | 165 | 18 | 125 | 4-18.5 |

| 65m.m | DIN 10 | 290 | 65 | 122*2 | 185 | 18 | 145 | 4-18.5 |

| 80m.m | DIN 10 | 310 | 75 | 138*3 | 200 | 20 | 160 | 4-18.5 |

| 100m.m | DIN 10 | 350 | 100 | 158*3 | 220 | 20 | 180 | 8-18.5 |

| 150m.m | DIN 10 | 400 | 150 | 212*3 | 285 | 22 | 240 | 8-44.2 |

2pc./3pc. full bore, floating ball

(above 2" hollow ball)

Non fire/Fire safe design

(Fire safe as per API 607)

Flanged end to ANSI B 16.5 RF

ANSI B 16.10

BS 6755, part-l &bs 5351

Multi port ball valve

Multi port ball valve3-way, 4-way, 5-way ball valve

Range : 1/2" to 6"

Rating : 150# & 300#

End connections : Flanged end & Screwed end

Standard ports : 'L' port, 'T' port, 'LL' port

Replacable seats & seals

Low torque for easy operation

Leak free operation

Screwed end, Socket WELD & Buttweld< ball valve

Range : 1" to 2"

Rating : 300# & 800#

End connections : Screwed, Socket WELD, Buttweld

Standard ports : 'L' port, 'T' port, 'LL' port

Construction : One piece, 2 piece & 3 piece

Remote Operated valve

Remote Operated valveOur industries Ball valves are suitable for power assisted operation. when the value operation needs assisted, our Industry provided

any kind of valve actuator e.g., Pneumatic, Hydraulic, Electric.

Our Industry will take full responsibility in selection of actuator of the most suitable size for operating condition.

The Pneumatically operated ball valves are provided with accessories like

In case of the ball valve installed in the underground pipe, the drain and the sealant injection bypass

should be piped to the top of the stem according to the burying depth specification of user's easy operation.

The dimension of the stem extension should be based on the distance between central line of valve body and top.

Design : BS 5351 / ANSI B 16.34 / API 6D / DIN

Testing : BS 6755 part 1 / API 598

Flange end : ANSI B 16.5

SW end : ANSI B 16.11

BW end : ANSI B 16.25

Screwed end : ANSI B 1.20.1 / ANSI B 2.1

Face to face : ANSI B 16.10/ API 6D

Fire safe : API 607, API 6 FA / BS 6755 part 2

Cast carbon steel : ASTM A 216 Gr. WCB/ WCC/ WCA

Cast Stainless steel : ASTM A 351 Gr. CF8M/CF8/CF3M/CF3

Cast allow steel : ASTM A 217 Gr. WC1/WC6/WCM/CA15

Cast low temp steel : ASTM A 352 Gr. LCB/LCC

Forged carbon steel : ASTM A 105

Forge steel : ASTM A 182 Gr. F316/F304/F316L/F304L

Forged Alloy steel : ASTM A 350 Gr. LF2

Hast alloy B&C, Cast iron etc.

Ball valves have successfully passed of API-607, using graphaite packing. Valves with PTFE packing have successfully passed BS 6755 certificates available upon request.